Satellite Alignment Metrology: Space vs Industrial Accuracy

That Monday morning scrap batch taught me why satellite alignment measurement isn't just about fancy gear, it's about engineering the entire system from lab to environment. Metrology tools don't magically deliver accuracy; they inherit uncertainty from every link in the chain. During a summer heatwave, our granite surface plate drifted beyond tolerance because we ignored thermal expansion coefficients. I logged hourly temperature shifts, correlated them to CMM measurements, and proved how a 5°C swing scrapped $28,000 in aerospace brackets. Management only approved environmental controls after seeing the data: 0.0004" error per °F in our 72" plate. Units and conditions specified. Today, I'll compare satellite and industrial metrology realities so you make a tolerance-driven pick, not just buy specs off a shelf.

Shop by tolerance stack, environment, and workflow, or accept drift.

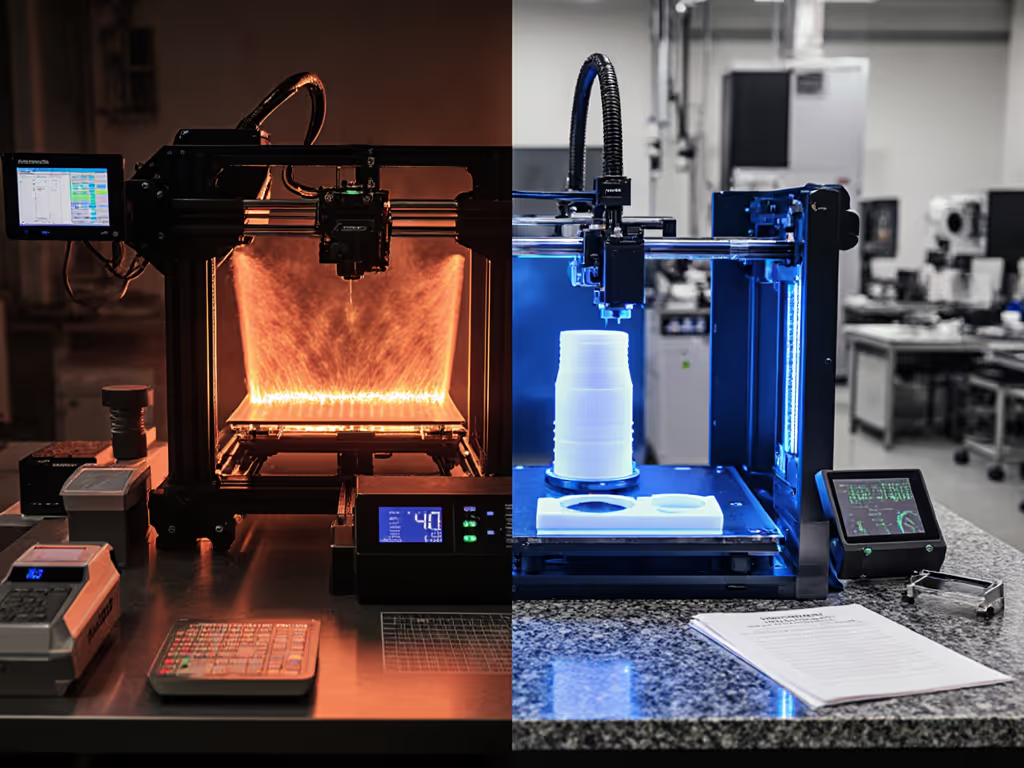

Why Satellite Metrology Requirements Differ From Industrial Applications

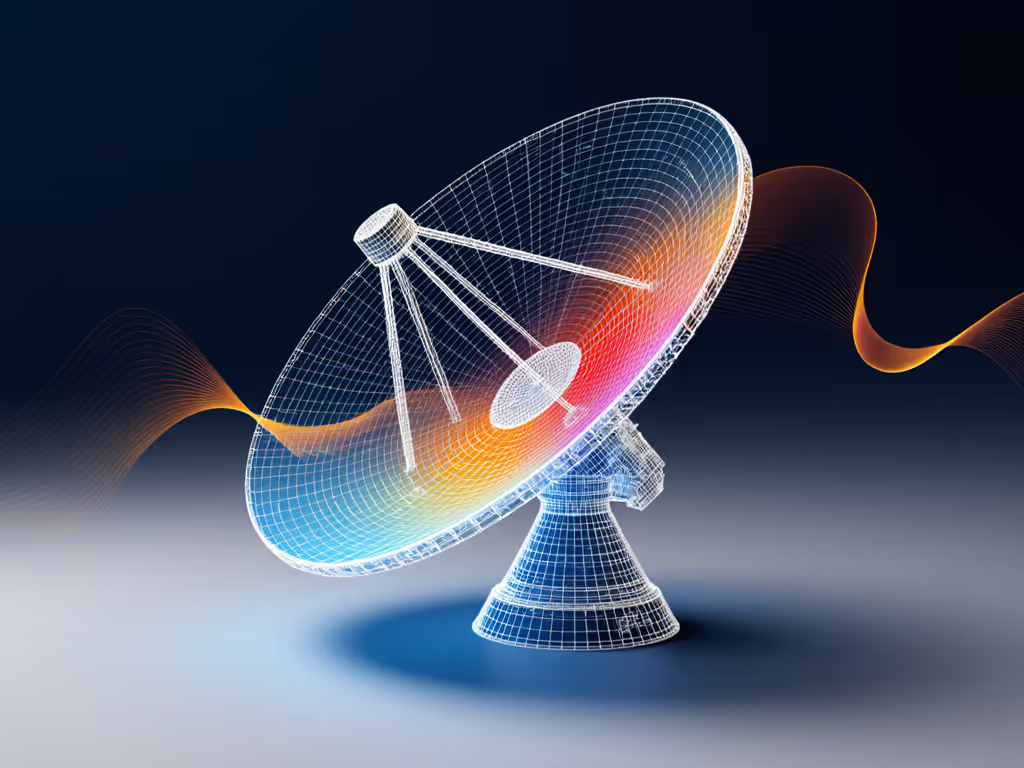

Satellite component alignment demands extreme precision, but the driver isn't resolution alone, it is survival in vacuum extremes. Consider antenna surface deformation: a 40°C temperature swing causes 0.216 mm RMSE shift (verified via photogrammetry), while 80°C jumps push it to 0.411 mm. Thermal stability in space isn't theoretical, it is measured in microns per degree. Yet industrial users often over-spec tools chasing satellite-grade numbers without context. To avoid this trap, use our tolerance-driven selection framework. Here is the critical distinction:

- Satellite needs: Nanometer stability across orbital cycles (e.g., -150°C to +120°C swings) with radiation-hardened sensors. Alignment must survive launch vibration plus zero-maintenance operation for 15+ years. Uncertainty budgets prioritize long-term drift over speed.

- Industrial needs: Micron stability within controlled shifts. My shop's ±2°C HVAC variance demands sub-5 ppm thermal error, but only for 8-hour shifts. Over-engineering for space-grade specs wastes capital when environmental controls would solve 90% of the problem.

The photogrammetry study from JAXA/ESA proves this: Their 0.3 mm RMSE requirement for orbital antennas used close-range bundle adjustment, not CMM metrology. Why? Because satellites face microgravity measurement techniques (no gravity-induced sag to compensate for). On Earth, we battle coolant splatter, floor vibration, and uncalibrated forklifts. Satellite deployment verification relies on vacuum-chamber testing, but your shop needs tolerance budgets for real-world coolant mist.

How Thermal Effects Break Down Measurement Chains (With Data)

Let's dissect uncertainty sources using actual error bars. In satellite antenna testing, thermal deformation dominates:

| Error Source | Satellite Environment (Vacuum) | Industrial Shop Floor | Mitigation Strategy |

|---|---|---|---|

| Thermal expansion | 0.411 mm @ 80°C swing (photogrammetry test) | 0.0004"/°F in granite plate | Environmental control + material matching |

| Vibration | Launch loads (20G+) | Forklifts (0.5G) | Isolation tables + active damping |

| Radiation | 100+ krad/year | Negligible | Radiation-hardened sensors (not needed) |

| Humidity | 0% (vacuum) | 30-80% swings | Sealed enclosures + desiccants |

Assumptions stated: Granite CTE = 5.5 ppm/°F; satellite antenna CTE = 23 ppm/°F; shop floor vibration measured at 10 Hz.

Notice satellite teams obsess over radiation-hardened sensors, but that's irrelevant in your facility. Meanwhile, most shops ignore humidity's 0.5 ppm impact on laser interferometers. My heatwave incident? Relative humidity dropped from 65% to 40%, shrinking our gauge blocks by 0.0001". That alone pushed us beyond 0.0005" tolerance. Supporting evidence: NIST study shows 1% RH shift = 0.02 ppm length change in steel. Units always matter. For a practical breakdown of common error sources and how to reduce them, see measurement error types.

FAQ: Bridging the Satellite-Industrial Measurement Gap

Q: Can industrial metrology tools handle satellite-component alignment?

A: Only if you reverse-engineer the tolerance stack. Satellite mirrors demand λ/20 surface accuracy (25 nm), but your optical bench CNC parts likely need 500 nm. Don't buy a $500k laser tracker for 5μm tolerances. Instead:

- Calculate your thermal error budget: For 0.001" flatness over 24", a 1°C shift = 0.00006" error (steel CTE). If your shop varies ±5°C, you need 0.0003" stability.

- Prioritize environmental control: A $15k HVAC system beats a $200k CMM upgrade. My shop's scrap rate dropped 73% after adding plate heaters and humidity sensors.

- Never assume resolution = accuracy. That "0.1μm" probe may hide 0.5μm hysteresis from cable drag. If that distinction trips you up, review accuracy vs precision with examples. Demand uncertainty budgets with all error sources quantified.

Q: Why do satellite teams use photogrammetry instead of CMMs?

A: Because physics changes in microgravity. Photogrammetry's RMSE of ≤0.3 mm (per ESA standards) works for large antennas because:

- No gravitational sag during measurement (unlike Earth-bound CMMs needing sag compensation)

- Vacuum eliminates air turbulence that distorts laser paths

- It is non-contact, critical for fragile composite surfaces

But on Earth? That same system would fail. Photogrammetry struggles with reflective shop-floor surfaces (oil, coolant) and vibrates if forklifts pass nearby. Key insight: Satellite tools solve orbital constraints, not industrial realities. I tested photogrammetry for turbine blade inspection, it failed MSA because fluorescent lights caused 0.002" scatter.

Q: How do I justify environmental controls to management?

A: Map scrap costs to thermal drift. When my heatwave incident happened, I built a business case using:

- Actual scrap data: $28,000/month from thermal drift

- Cost of control: $42,000 HVAC + $18,000 plate heaters

- ROI: 2.3 months payback ($28k x 12 months = $336k annual savings)

The spreadsheet showed exactly how 0.0001" tolerance loss = $1,600/week in aerospace brackets. Management approved funding that afternoon. Pro tip: Frame controls as calibration interval extenders (stable temps cut gauge block recalibration from quarterly to annually).

The Non-Negotiables for Industrial Metrology Success

Satellite teams have NASA-grade budgets, but you work with ISO 9001 constraints. Here's how to close the gap without overspending:

- State your assumptions explicitly:

- "0.0005" accuracy assumes 68-72°F, 45% RH, granite plate calibrated yesterday."

- Without this, specs are meaningless. Boeing's 2024 audit found 62% of shop-floor measurements omitted environmental conditions.

- Demand traceable uncertainty budgets:

- If a supplier won't share error sources (thermal, cosine, repeatability), walk away. My rule: Total uncertainty must be ≤20% of your tolerance.

- Example: For 0.001" hole tolerance, tool uncertainty ≤0.0002". Verify via NIST-traceable gauge blocks in your shop conditions. For a step-by-step approach to calculating this, use our measurement uncertainty budget guide.

- Engineer the environment first:

- Spend 30% of your metrology budget on environmental controls. A $5k thermal enclosure for micrometers often outperforms a $50k CMM in unstable shops.

- Monitor continuously: Data loggers costing $200/day prevented $220k in scrap at Lockheed's facility last year.

- Validate your workflow, not the spec sheet:

- Test tools with your parts, your operators, your shop-floor vibration. A $10k indicator might fail where a $3k one succeeds due to better thermal mass.

- Run GR&R studies with coolant running, that's when cosine error destroys accuracy.

Final Thought: Capability > Calibration

Satellite metrology succeeds because they engineer systems, not buy tools. The OCO-2 satellite's 1 ppm RMSE for CO2 measurements came from balancing thermal stability, sensor alignment, and orbital timing, not just a high-end spectrometer. On your shop floor, matching CMM and micrometer data requires the same systems thinking. I still see engineers chase "sub-micron" claims while ignoring 10°F temp swings between their lab and production floor. Until you control environment, process, and tool interaction, you're gambling with scrap rates.

Further Exploration: Ready to audit your measurement uncertainty? Download my Thermal Error Budget Calculator (free for ISO-certified shops). It auto-generates drift projections based on your material CTE, tolerance, and local weather history. Input your shop's specs, and it calculates break-even points for environmental controls (no sales pitch, just physics). Because when the next heatwave hits, you'll know exactly how many degrees you can afford to lose.

Shop by tolerance stack, environment, and workflow, or accept drift.