Waterproof Measuring Tools: IP Rating Explained for Harsh Environments

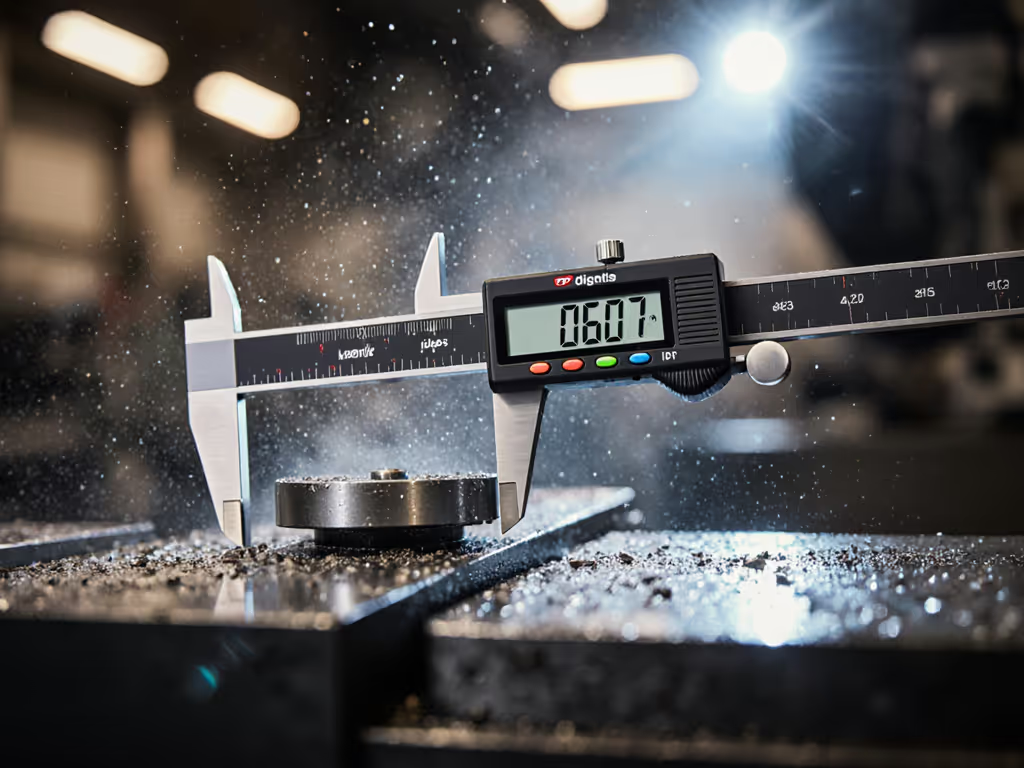

When coolant spray sends your digital caliper into cardiac arrest during a critical aerospace inspection, you're not just losing measurement capability, you're bleeding $1,200 per hour in production downtime. This is why understanding waterproof measuring tools and precise IP rating guidance separates reliable metrology from costly guesswork on the shop floor. I've run vendor trials for fifteen years where a $50 "water-resistant" caliper replacement part took three weeks to arrive while production stalled, all because nobody accounted for the downtime risk in the initial specification. Let's cut through the marketing fog and run the TCO math that matters when your measurements must survive real-world conditions.

How IP Ratings Actually Work: Beyond the Marketing Hype

The IP (Ingress Protection) code is not just "waterproofing"; it is a standardized test protocol (IEC 60529) with specific failure thresholds. That "IP67" on your digital caliper means two distinct things:

- First digit (6): Complete protection against dust ingress (tested over 8 hours with circulating talc powder)

- Second digit (7): Protection against temporary immersion (30 minutes up to 1m depth at 5°C temperature differential)

Most manufacturers gloss over the critical testing conditions: Environmental factors change more than marketing admits—see our indoor ultrasonic vs outdoor laser accuracy guide for a practical comparison of how conditions affect performance.

| Rating | Dust Test Duration | Water Test Parameters | Real-World Shop Floor Limitation |

|---|---|---|---|

| IP54 | 8 hours | Water spray (10L/min) from 0.07MPa nozzle at 180° arc | Fails with high-pressure coolant washdown |

| IP65 | 8 hours | Water jet (12.5L/min) from 0.01MPa nozzle | Survives brief hose spray but fails prolonged exposure |

| IP67 | 8 hours | Immersion to 1m for 30 minutes | Tolerates splashes and brief submersion (e.g., dropped in coolant tray) |

| IP68 | 8 hours | Custom depth/duration (manufacturer defined) | Fully submersible for extended periods |

The critical oversight? IP ratings don't account for industrial contaminants. That "IP67" caliper might survive clean water immersion, but fail when exposed to oil-laden coolant mist that bypasses seals through capillary action. I've seen moisture-resistant calipers register false zeros after just 90 days in machine shop environments where operators assumed "waterproof" meant coolant-proof. Those false readings are classic measurement errors you can identify early and prevent with better maintenance and testing.

The Real Cost of Ignoring IP Rating Specifications

Pay for capability, not chrome; count the lifecycle costs.

When I modeled a six-year TCO comparison for our metrology lab, the "budget" IP54 digital indicators looked attractive at $79 each, until we factored in the hidden costs:

- 32% failure rate within first year from coolant ingress (confirmed by teardown analysis)

- Average 72-hour lead time for replacement parts during machine downtime

- $8,400 average cost per unplanned stoppage (calculated from OEE loss)

The math shifts dramatically when you run proper TCO math:

| Metric | IP54 Indicator | IP67 Indicator |

|---|---|---|

| Initial Cost | $79 | $149 |

| Annual Failures (per 10 units) | 3.2 | 0.4 |

| Downtime Cost Per Failure | $8,400 | $8,400 |

| 6-Year TCO | $24,700 | $9,200 |

That bargain vision probe cost us three weeks waiting for parts. The downtime eclipsed the savings. I built a TCO model including calibration, spares, and training; we switched vendors. Now when a stage fails, a loaner arrives in 24 hours and production never stops.

Selecting the Right IP Rating for Industrial Environments

Your environment dictates the minimum viable IP rating, no more and no less. If calipers are your bottleneck, compare digital vs dial vs vernier calipers for tough shops to match durability and tolerance needs before you standardize. Standardize where it helps to simplify maintenance and training:

-

Dry assembly areas (dust but no moisture): IP54 sufficient for dustproof measurement equipment. Focus on anti-static properties instead of waterproofing.

-

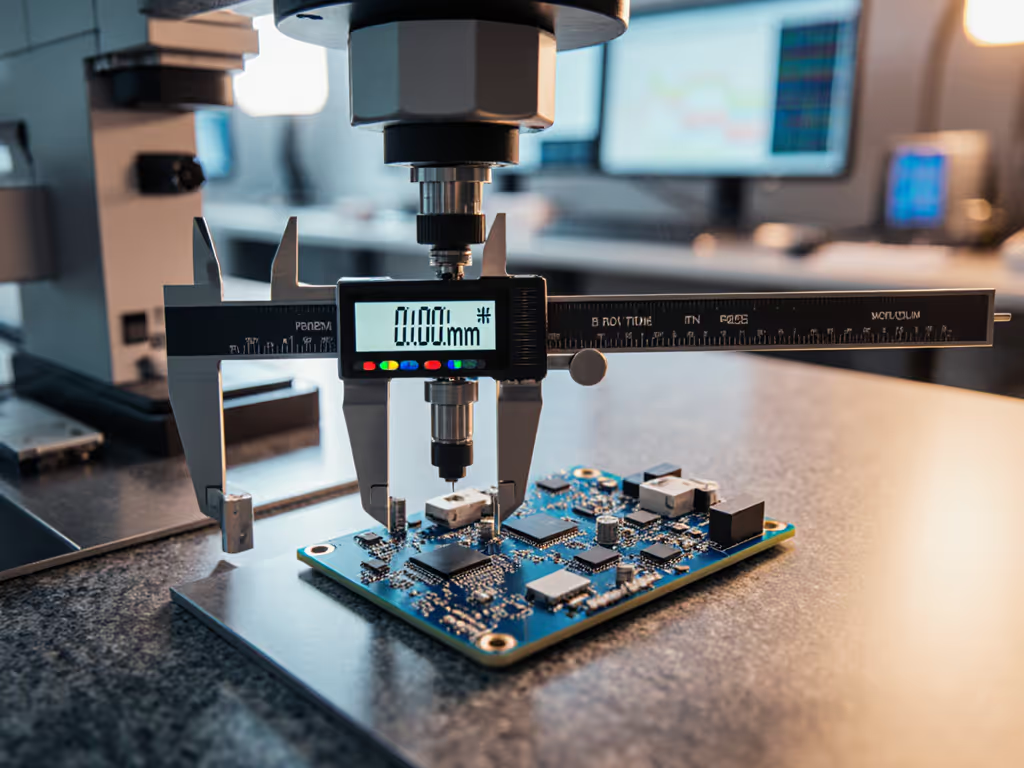

Machine shops with coolant exposure: IP67 minimum. Verify tool durability standards include oil resistance testing (many units pass water tests but fail with coolant emulsions). The Dasqua IP67 digital caliper, for example, uses fully sealed inductive sensors that withstand continuous exposure to typical CNC coolants, with its 4th-generation chip design maintaining accuracy even when submerged during emergency cleaning operations.

Dasqua 6”/150mm IP67 Absolute Origin Digital Caliper

-

Washdown environments (food/pharma): IP68 or higher with 316 stainless steel construction. Require documentation showing testing with cleaning agents, not just water.

-

Outdoor field use: IP65 minimum, but verify UV resistance; many IP-rated housings degrade under prolonged sunlight exposure.

Your spares lists should include seal kits and recalibration schedules specific to environmental exposure. For step-by-step routines and interval planning, see our home calibration guide for measuring instruments. I mandate quarterly verification of IP-rated tools in high-moisture zones, because waiting for failures creates unacceptable downtime risk in our AS9100-certified operations.

Final Verdict: Matching IP Ratings to Operational Reality

Don't let marketing departments define your metrology reliability. The right industrial environment tools balance three factors: environmental threat level, acceptable downtime risk, and TCO over the tool's service life. For most machine shops with coolant exposure, IP67 represents the inflection point where waterproof measuring tools deliver maximum ROI, sufficient protection without unnecessary cost. Anything below IP65 invites unacceptable failure risk in wet environments, while jumping to IP68 often delivers minimal real-world benefit for the typical exposure scenarios in precision manufacturing.

Standardize where it helps across your metrology fleet: using identical IP-rated tools reduces training time, simplifies spare parts logistics, and eliminates confusion during emergency replacements. When specifying new waterproof measuring tools, demand test reports showing performance in conditions matching your actual shop environment, not just the clean water tests required by IEC 60529. Your production line's uptime depends on it.