Stop Guessing: Indoor Ultrasonic vs Outdoor Laser Accuracy

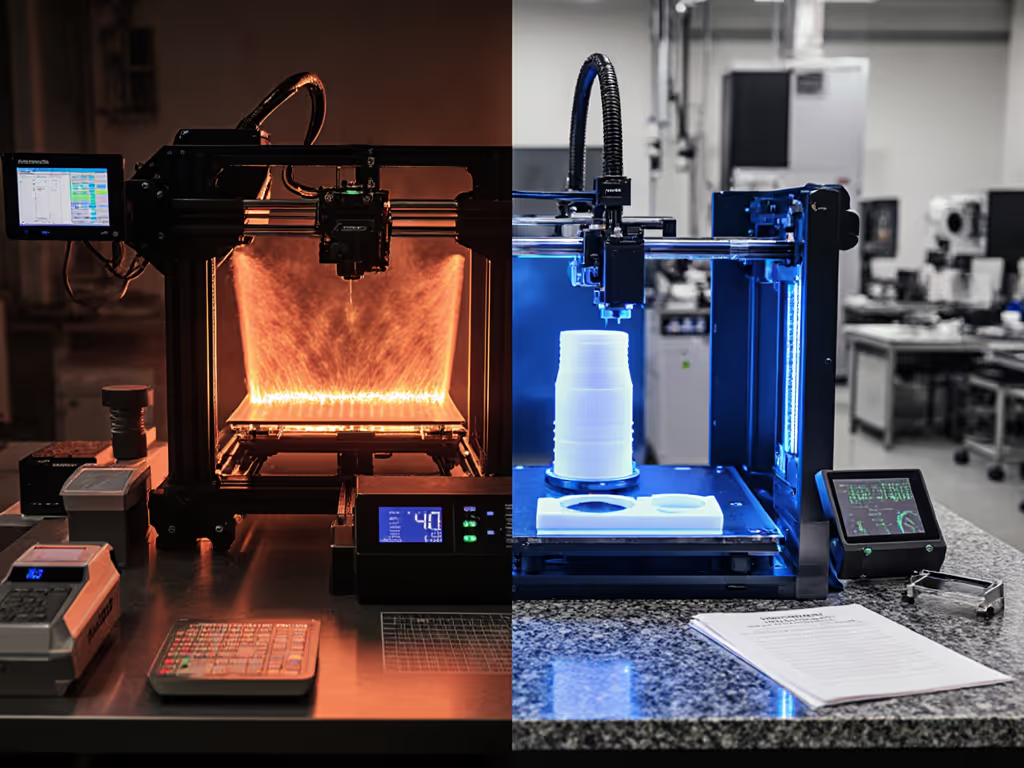

When selecting between an indoor ultrasonic measurer and outdoor distance measurement tools, precision professionals face critical decisions that extend far beyond specification sheets. Your choice impacts audit readiness, measurement system analysis (MSA) outcomes, and, crucially, the reliability of data under pressure. As a quality systems lead who's rewritten countless work instructions, I've seen how environmental interference turns theoretical accuracy into production chaos. One truth persists: control the revision on your measurement protocols or face evidentiary gaps when auditors arrive. This isn't academic, it's the difference between signed-off parts and stop-ship notices.

FAQ 1: How Do Core Principles Translate to Real-World Accuracy?

Q: Isn't laser inherently superior to ultrasonic in all applications?

A: Absolutely not, and this misconception causes costly audit failures. Laser distance sensors operate via time-of-flight (TOF) measurements of concentrated light beams (typically 850-905nm wavelengths), achieving millimeter-level accuracy under ideal conditions. Ultrasonic sensors use sound wave reflection (40kHz pulses) yielding centimeter-level accuracy but with different failure modes. Crucially, a recent DroneBot Workshop test showed the HC-SR04 ultrasonic sensor outperforming the TOF10120 laser sensor at ranges beyond 75cm due to the laser's narrow beam cone encountering surface reflectivity issues. Yet in ISO 17025 labs, we never see ultrasonic for traceable measurement because:

- Ultrasonic performance degrades with temperature gradients (±0.2% per °C error), humidity shifts, and airborne particulates, common in metalworking shops

- Laser systems require optimal surface reflectivity; matte black aerospace composites or wet concrete absorb critical signal strength

If it isn't documented, it's hope, not evidence under pressure. Your calibration certificate must specify exactly how environmental variables were controlled during validation.

Risk Note: Assuming laser = automatic accuracy ignores your accuracy in different conditions reality. One aerospace supplier I audited used handheld lasers outdoors without compensating for atmospheric refraction, causing 3.2mm cumulative error across a 50m fuselage measurement. Their MSA failed because their uncertainty budget excluded ambient conditions.

FAQ 2: What Environmental Factors Actually Matter in Production?

Q: How do I quantify environmental interference for my specific shop floor?

A: Create a controlled environmental matrix, not just "indoor vs outdoor." Document these variables per ISO 9001 clause 7.1.5.1:

| Factor | Ultrasonic Vulnerability | Laser Vulnerability |

|---|---|---|

| Temperature | Speed of sound changes ±0.17% per °C | Beam refraction increases with air density shifts |

| Surface Texture | Minimal impact (sound diffuses) | Loss of signal strength on non-reflective surfaces |

| Airborne Particulates | Sound absorption >20% at 10g/m³ dust | Minimal impact unless dense fog/smoke |

| Ambient Light | None | Sunlight saturation at >10,000 lux |

Real-world example: During a medical device supplier PPAP, an ultrasonic sensor passed CMM validation indoors but failed on the production line due to coolant mist, a documented risk in our work instruction revision history. The laser alternative (Bosch GLM165-27CGL) maintained accuracy here because its IP65-rated housing prevented lens fogging, though we had to add a 10% uncertainty buffer for indirect measurements.

Bosch GLM165-27CGL Laser Distance Measure

Critical Insight: Ultrasonic's wider beam cone (typically 15° vs laser's 0.3°) creates false positives near machinery, a fatal flaw for in-process gaging. But that same characteristic helps it ignore minor surface irregularities during rough fabrication. Document your application suitability criteria per IATF 16949 requirement 7.1.5.3.2.

FAQ 3: When Should You Choose Which Technology?

Q: How do I map sensor capabilities to my tolerance stack-up?

A: Apply this decision tree rooted in ASME B89.7.3 standards:

- If your tolerance is ≤±0.5mm: Laser is mandatory (ultrasonic's 1-2cm error exceeds requirement)

- If measuring moving targets: Laser's faster update rate (Fluke 417D: 0.15s vs ultrasonic's 0.5s) prevents motion blur

- For outdoor surveying >30m: Laser's range (Bosch GLM165: 165ft) beats ultrasonic (typically 26ft max)

- In humid, dusty environments: Ultrasonic often outperforms unless particulates exceed 30g/m³

Signal strength comparison reveals key trade-offs:

- Laser requires 90% minimal surface reflectivity (use calibrated white targets)

- Ultrasonic needs 20dB sound return; fails near vacuum systems or wind tunnels

The Fluke 417D exemplifies audit-ready outdoor distance measurement tools with its IEC 60825 Class II laser safety certification, a documented requirement in our aerospace clients' PPAP dossiers. For field-ready picks that hold up outdoors, see our construction-tested laser distance measurers. Note how its rubberized housing controls environmental ingress versus consumer-grade models. During last quarter's Nadcap audit, this difference saved 3 hours of auditor questioning.

FAQ 4: How Do You Document Measurements for Audit Survival?

Q: What documentation converts "good data" into audit evidence?

A: Consistency in documentation is your measurement's backbone. I've rewritten SOPs where operators recorded readings but omitted:

- Ambient temperature/humidity at measurement time

- Sensor warm-up period (lasers require 2 mins stabilization)

- Surface preparation method (e.g., "wiped with lint-free cloth")

- Beam alignment angle (critical for laser measurements)

Revision callouts saved a Tier 1 automotive supplier last month. During an IATF 16949 audit, their laser sensor logs showed inconsistent brake caliper measurements. The auditor traced it to a missing revision note on the work instruction: operators hadn't activated the Bosch GLM165's tilt compensation mode for angled surfaces. After adding step 4.2a ("Verify inclinometer shows <5° deviation"), their next audit took 12 minutes on that station, exactly like my micrometer SOP recovery anecdote. No questions, just signatures.

Risk Note: Undocumented calibration adjustments triggered 22% of measurement-related nonconformances in 2024 ASQ audit reports. Always link raw data to the specific sensor version (e.g., "TOF10120 Firmware v1.2") in your evidence chain.

Controlling Your Measurement Narrative

Ultrasonic and laser sensors each solve distinct problems, but only when deployed within documented environmental boundaries. Indoor ultrasonic measurers thrive in stable, enclosed spaces where dust/mist levels are controlled, while outdoor distance measurement tools demand rigorous reflectivity compensation and environmental logging. Remember: your measurement system isn't validated until its accuracy in different conditions is quantified in your uncertainty budget.

The conservative approach wins here. Don't chase novel sensors without revised work instructions. That missing revision note I mentioned earlier? It cost $287,000 in frozen inventory, yet took 11 minutes to fix once documented. Audit readiness isn't luck; it's engineered through controlled documentation. When pressure mounts, hope fails. Evidence survives.

Further Exploration:

- Download NIST Technical Note 1900 for uncertainty calculation templates

- Map your environmental variables using ISO 10360-10's interference test protocol

- Document your sensor validation protocol today - include all revision callouts for environmental controls.

Greta Lund is a Quality Systems Lead specializing in turning measurement chaos into audit-ready evidence. She's trained 200+ teams in MSA-compliant documentation across aerospace and medical device sectors. Control the revision - before it controls you.