Digital vs Dial vs Vernier Calipers: Pick Right for Tough Shops

If operators can't repeat it, it doesn't measure. That simple truth haunts me every time I walk onto a shop floor where measurement errors trigger scrap, rework, and audit headaches. Today, we're cutting through the noise of digital vs dial vs vernier calipers marketing to solve your real problem: choosing the right tool that actually works when gloves are on, coolant is flying, and takt time is breathing down your neck. This caliper type comparison isn't about specs on paper (it's about what happens when human hands meet measurement tools under production pressure).

Why Your Caliper Choice Is Costing You More Than You Think

Last Tuesday, I watched a seasoned operator eyeball a digital display while his thumb pressed the jaws at inconsistent angles. Same caliper, same part, wildly different readings. That's not a tool failure, it's a human-tool interface disaster. Too many teams treat caliper selection like picking a coffee mug: "Which looks nice?" Instead, you need to engineer the measurement into your workflow. When I swapped a beloved digital caliper after discovering operators 'thumbed' different pressure, a simple force-limiting device and a two-minute teach-back cut our GR&R from 38% to 12%. The part didn't change; the handling did.

Here's what's really at stake:

- Scrap costs that skyrocket when measurement variation exceeds your tolerance stack

- Audit failures from inconsistent GR&R that can't be traced to operator technique

- Lost productivity when technicians fight glare, dead batteries, or confusing vernier scales during changeovers

- False confidence from spec sheets that never account for grease, vibration, or glove interference

Digital vs Dial vs Vernier Calipers: Shop-Floor Reality Check

Let's cut through the marketing fluff and compare these tools where it matters, on your actual production line.

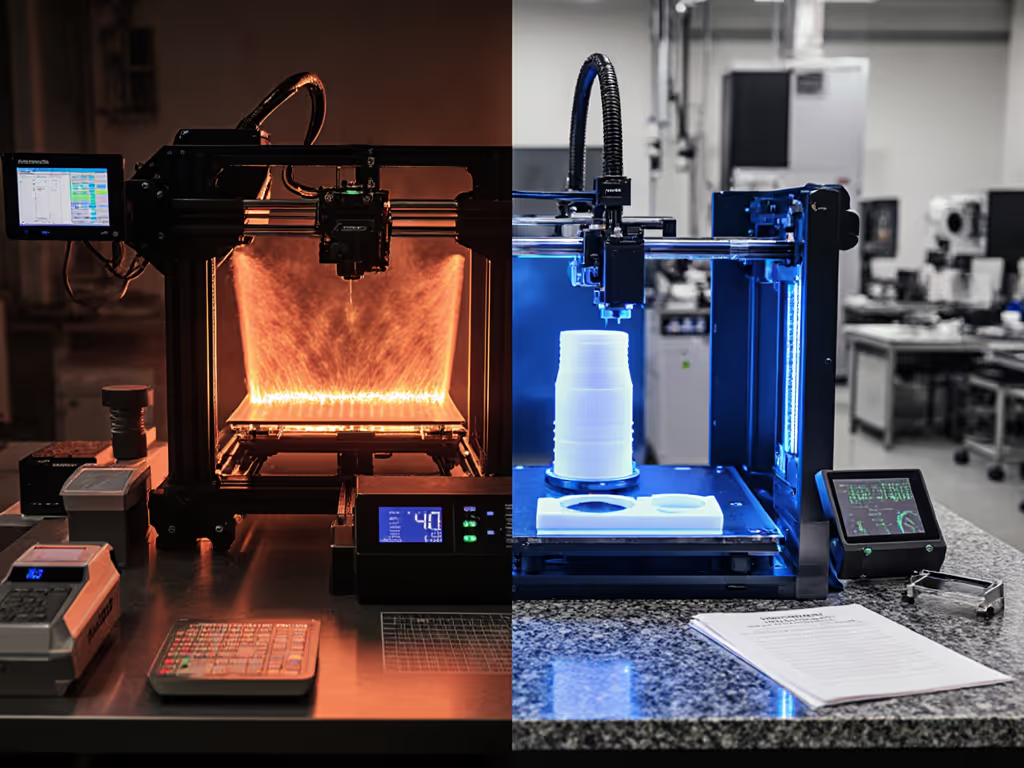

Digital Calipers: Speed Trap or Shop Savior?

Digital calipers promise speed and convenience, but in harsh environments, they often deliver frustration. I've seen more production lines derailed by dead batteries during critical runs than I care to admit. The LCD glare under shop lights? Forget it. And don't get me started on the moisture sensitivity, just one splash of coolant can send your readings haywire.

When to Choose Digital:

- In climate-controlled clean rooms or final inspection stations

- When you need unit conversion on-the-fly for mixed units

- For operators with visual limitations who need large digital displays

Shop-Floor Reality Check: The resolution looks great on paper, but the supposed ease of reading disappears when you add grease, gloves, and time pressure. Digital tools demand perfect conditions to deliver their promised accuracy. And that Bluetooth connectivity? More often a headache than a help when your SPC system drops half the data points.

Starrett Electronic Slide Caliper

That's why I'm selective about digital calipers. When I do specify them, I require features like the Starrett EC799's automatic shutoff (prevents forgotten-on battery drain) and hardened stainless steel measuring surfaces. Its .0005" resolution means something only when coupled with proper operator training on consistent probe force. A teach-back cue I use: "Squeeze like you're holding a baby bird, firm but gentle."

Remember: Resolution isn't repeatability. A digital readout with four decimal places won't save you from inconsistent handling.

Dial Calipers: The Underestimated Workhorse

Dial calipers get dismissed as "old school" until you're in a wet, oily environment where digital displays fail. No batteries means no dead-tool emergencies. The dial face works in direct sunlight where digital displays wash out. But that rack-and-pinion mechanism? One solid drop can knock it out of alignment, and operators constantly misread the dial when they're rushed.

When to Choose Dial:

- In wet or oily environments where moisture kills digital tools

- For mid-precision applications where 0.001" is sufficient

- When you need to work in bright light conditions where LCDs become unreadable

Shop-Floor Reality Check: The tool longevity comparison favors dial calipers in harsh conditions, but only if you implement visual anchors for quick reading. I've taped red dots at 0.000", 0.005", and 0.010" on the dial face (operators check three points instead of deciphering the whole scale). And that thumb pressure issue? Dial calipers expose inconsistent force immediately through erratic needle movement, a built-in teach-back tool!

Mitutoyo 505-742J Dial Caliper

The Mitutoyo 505-742J's dial movement is engineered for shock resistance, but even it needs protection from heavy impacts. My standard procedure: operators perform a quick zero-check at shift start AND after any potential drop. Simple? Yes. But I've seen this reduce measurement variation by 17% in automotive press shops where vibrations play havoc with delicate instruments.

Vernier Calipers: The Forgotten Fortress

"Who uses verniers anymore?" I hear you ask. Try aerospace turbine shops and medical device clean rooms where absolute reliability trumps speed. No batteries, no electronics, no fragile components, just hardened steel and human skill. But the caliper reading difficulty is real, especially for newer technicians trained on digital displays.

When to Choose Vernier:

- In extreme environments with high EMI, moisture, or temperature swings

- Where absolute reliability is non-negotiable (think medical or defense)

- For calibration labs verifying other measurement tools

Shop-Floor Reality Check: The environment suitability of verniers is unmatched, but they demand proper training. I break vernier reading into three visual anchors: whole number, major division, and vernier coincidence. For step-by-step techniques and practice tips, see our vernier scale reading guide. A 10-minute teach-back session where operators explain the reading process cuts errors by 63% in my experience. And yes, verniers can work with gloves (they're the ultimate glove-on usability tool when other types fail).

Your Caliper Selection Checklist: No More Guesswork

Skip the spec sheet bingo. Use this operator-first checklist when choosing your next caliper:

Step 1: Assess Your Environment (Be Brutally Honest)

- ☑️ Moisture level: Coolant spray? Direct washdown? Choose analog if wet

- ☑️ Temperature range: More than 20°F swing? Avoid digital electronics

- ☑️ Vibration level: Near presses or mills? Dial calipers suffer most here

- ☑️ Lighting conditions: Direct sunlight? Digital displays fail first

Step 2: Match to Operator Reality

- ☑️ Training level: New techs? Start with digital for ease, but add force training

- ☑️ Glove requirements: Full leather gloves? Vernier wins for glove-on usability

- ☑️ Takt time pressure: Under 30 seconds per check? Digital's speed matters

- ☑️ Eyesight considerations: Older workforce? Larger dial faces beat vernier scales

Step 3: Verify Workflow Integration

- ☑️ Zero-point stability: Can operators recalibrate mid-shift without tools?

- ☑️ Measurement frequency: Every 10 parts? Digital battery life becomes critical

- ☑️ Data capture needs: Real-time SPC? Test Bluetooth reliability FIRST

- ☑️ Storage conditions: Floating bridge crane station? Choose sealed tools

Make Your Decision Stick: Beyond the Purchase Order

Buying the right caliper is just step one. My proven technique for embedding measurement success:

- Conduct a GR&R before full rollout: Test with actual operators in real conditions, not just metrology experts

- Create visual setup guides (photos showing proper grip, jaw placement, and force technique)

- Implement teach-back verification: "Show me how you'd explain this to a new hire"

- Schedule zero-check reminders: Every 2 hours for digital, every shift change for analog

- Track tool survival rate: How many survive 6 months of actual shop use?

Last month at a defense contractor, we implemented this process for a critical turbine blade inspection. They'd been using delicate digital calipers that failed weekly in the oily environment. We switched to rugged dial calipers with visual zero markers and 30-second force training. GR&R dropped from 41% to 14% in two weeks. Analog vs digital measurement wasn't the issue, the human-tool interface was.

Your Actionable Next Step: One Shift, One Caliper, One Win

Don't overhaul your entire measurement program today. Pick ONE critical measurement point where scrap rates are high or GR&R fails. Grab three caliper types (yes, borrow them if needed). Have your operators measure the same part, same feature, 10 times each with gloves on. Record the variation, not the absolute values. Then ask:

"Which tool delivered consistent results when operators were rushed, gloved, and under production pressure?"

That's your winner. Not the fanciest specs, not the shiniest display, but the tool that survives your shop-floor reality. Implement our 5-step verification, track the results for 30 days, and calculate your scrap reduction. When you see those numbers, you'll understand why repeatable measurement isn't about the tool (it's about how humans touch tools).

Your move: Tomorrow morning, grab that high-scrap work order and run the 10-measurement test. Document what you find. Then come back here and share your results, I'll help you interpret them. Because in the end, the best caliper is the one your operators can use consistently, shift after shift, without slowing takt time. That's true glove-on usability.