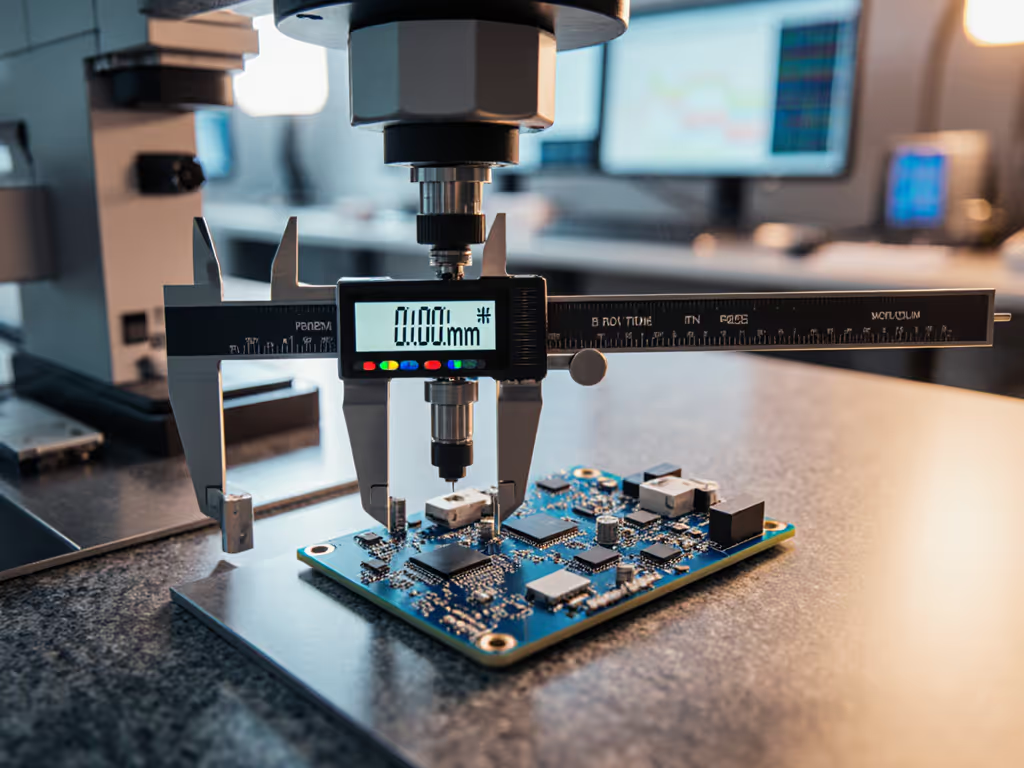

Ensure Tool Accuracy: Home Calibration Guide for Measuring Instruments

As a former calibration lab technician turned quality advisor, I've seen how measuring instrument calibration separates production-ready shops from those constantly fighting scrap and rework. A proper home calibration guide isn't just about checking tools, it's about establishing confidence in your measurements when formal lab access is limited. When your Starrett caliper reads 0.0005" tolerance on a critical aerospace fitting, you need to know that number carries traceability all the way to NMI standards. In this audit-ready framework, I'll show you how to maintain tool accuracy without compromising on documentation rigor.

Trace it, budget it, then trust it under audit.

Understanding the Calibration Fundamentals

What exactly constitutes "calibration" versus simple verification?

Calibration establishes metrological traceability by comparing your instrument against a higher-accuracy reference standard with documented uncertainty. It's not merely checking if a tool "works," it's quantifying measurement uncertainty across the instrument's operating range. Many technicians confuse verification ("does it read within tolerance?") with proper calibration ("what's the exact error at multiple points, with documented uncertainty?"). If you're unclear on accuracy vs precision, start with our practical guide.

True calibration creates an uncertainty budget that accounts for:

- Reference standard uncertainty

- Environmental contributions (temperature, humidity, vibration)

- Operator technique variability

- Instrument resolution and hysteresis

Skipping this structured approach leaves you vulnerable during audits. I once watched an auditor shift from skeptical to supportive when we produced not just our CMM room thermometer calibration certificate, but the complete traceability chain showing how that thermometer linked back to NMI standards. That moment cemented my belief: traceability creates trust.

Why environmental control matters more than you think

Temperature variations of just 1°C can introduce 11.5μm/m of error in steel measurements. Your garage workshop likely experiences wider swings than the 20°C±1°C environment specified in ISO 1. Your calibration becomes meaningless if you don't document:

- Ambient temperature at calibration points

- Thermal stabilization time (minimum 4 hours for steel tools)

- Relative humidity (critical for moisture-sensitive instruments)

For home calibration, establish a dedicated 3'x3' zone with:

- Digital thermometer/hygrometer (calibrated annually)

- Thermal mass platform (marble slab ideal)

- Draft protection (closed room, no direct HVAC flow)

Creating Audit-Ready Documentation

What documentation must accompany home calibration?

Document before you defend, that principle saved my team during an AS9100 audit. Your calibration records must include:

- Instrument identification (make, model, serial number)

- Reference standards used (with calibration certificates)

- Environmental conditions during calibration

- Pre-adjustment readings at multiple points

- Adjustment details (if performed)

- Post-adjustment verification data

- Uncertainty budget calculation

- Calibration interval justification

- Technician signature and date

Starrett Electronic Slide Caliper

How do I establish traceability without lab access?

Your reference standards must create an unbroken chain to national standards. For home calibration:

- Start with certified reference materials (e.g., Grade 0 gage blocks)

- Verify these against your highest-accuracy tool

- Document each comparison step with dated records

When calibrating a digital caliper like the Starrett EC799, use gage blocks with certified values traceable to NIST. Measure at 0, 1/3, 2/3, and full scale, recording both the block's certified value and your instrument's reading. This creates your foundational uncertainty data.

Developing Practical Calibration Procedures

What's the right calibration frequency for shop tools?

Your calibration frequency must balance risk against practicality. Don't default to arbitrary 6-month intervals. Instead:

- Analyze historical performance data (if available)

- Consider usage intensity (100 measurements/day vs 10)

- Evaluate consequences of failure (medical device vs woodworking)

- Monitor environmental stability

Create a tiered system:

| Tool Criticality | Initial Interval | Adjustment Trigger |

|---|---|---|

| Critical (safety/aerospace) | 3 months | 2 consecutive out-of-tol readings |

| Production control | 6 months | Visual damage or impact |

| Non-critical layout | 12 months | Operator suspicion of error |

What are reliable DIY calibration methods for common tools?

Digital calipers: Verify at multiple points using gage blocks. Record repeatability by taking 10 consecutive measurements on the same block. Acceptable variation should be ≤ 1/4 of your tolerance.

Dial indicators: Use a precision v-block and master cylinder. Check for hysteresis by loading/unloading at multiple points.

Combination squares: Check against a calibrated surface plate and precision angle block. Measure both 90° and 45° faces at multiple locations along the blade.

Critical note: Never use "known good parts" as calibration standards. Their dimensions aren't traceable, creating false confidence. Invest in proper reference materials (your quality system depends on it).

Maintaining Long-Term Accuracy

How do I build an uncertainty budget for home calibration?

Your tool accuracy maintenance requires understanding all error sources. For a typical digital caliper:

Standard uncertainty components:

- Reference standard: 1.5μm (k=2)

- Temperature effects: 2.3μm (ΔT=1.5°C)

- Repeatability: 0.8μm (from 10 measurements)

- Resolution: 0.29μm (0.5μm resolution/√12)

Combined uncertainty: √(1.5² + 2.3² + 0.8² + 0.29²) = 2.8μm

Expanded uncertainty (k=2): 5.6μm

This budget shows you can reliably measure 0.001" (25.4μm) tolerances, but not 0.0002" (5μm). Many shops skip this analysis and unknowingly measure beyond their capability.

What's the most overlooked factor in home calibration?

Operator technique. I've seen skilled machinists unknowingly introduce 0.0005" errors through inconsistent probe pressure. Standardize technique with:

- Fixed-force measurement stands

- Written procedure specifying "just-contact" force

- Annual technique verification using force gauge

- Training records showing competency

Moving Forward with Confidence

Your calibration system should create calm confidence, not audit anxiety. Implement these three steps immediately:

- Designate a documented calibration zone with environmental monitoring

- Create traceability chains for all reference standards

- Start recording uncertainty budgets, not just pass/fail results

Remember: proper calibration isn't about perfect measurements, it's about known measurements. When you can trace your thermometer to NMI standards and quantify every uncertainty contributor, you transform from reactive firefighter to proactive quality engineer. That's when audits become validation of your discipline, not interrogation of your documentation.

For further exploration, study ISO/IEC 17025 requirements for measurement traceability and NIST Special Publication 1008 on field calibration best practices. The most successful shops don't chase calibration perfection, they build systems where measurement trust is engineered into every process.