Beyond Specs: Non-Contact Metrology Reality Check

Forget the glossy spec sheets boasting "sub-micron resolution" or "800-foot laser range." As a procurement engineer who's modeled the non-contact measurement comparison nightmares for aerospace and medical device plants, I've seen too many teams derailed by headline specs that ignore real-world costs. The truth? Your contactless metrology decision must survive three critical tests: Can it prevent downtime when the spindle breaks at 2 AM? Will it hold up through coolant splashes and temperature swings? And, crucially, does its TCO math actually save money over its lifecycle? Let's cut through the marketing.

Why Your Spec Sheet Lies (And What Matters Instead)

You've seen it: a supplier's brochure screaming "0.5µm accuracy!" while quietly burying the fine print (in temperature-controlled lab conditions, averaged over 100 measurements). But in my machine shop? Temperature swings 15°C between dawn and noon. Coolant fogs lenses. Operators wear gloves. That shiny spec isn't your reality. To see how environment, technique, and setup bias measurements, review our measurement error types guide.

The hard truth I learned after a $1,200 bargain vision probe failed (and cost us 72 hours of production waiting for a replacement lens): downtime risk dwarfs upfront savings. A CMM might cost 30% less than a multi-sensor platform, but if its probe head fails during a critical aerospace run, your facility burns $18,000/hour in idle labor and missed shipments. That's why I audit service terms and spares lists before even checking resolution.

The Hidden Cost Drivers Nobody Talks About

| Cost Factor | Contact Systems (CMM, LVDT) | Non-Contact Platforms |

|---|---|---|

| Downtime Risk | High (probe collisions, recalibration after crashes) | Medium (sensor fouling, software errors) |

| Calibration Burden | Frequent (mechanical wear affects accuracy) | Moderate (optical drift less predictable) |

| Environmental Tolerance | Handles dust, coolant, vibration better | Sensitive to fogging, EMI, ambient light |

| 100% Inspection Capability | Impractical (slow cycle times) | Yes (critical for medical/avionics) |

| Hidden TCO Items | Replacement tips, alignment artifacts | Sensor recalibration, air knives, anti-reflective spray |

Pay for capability, not chrome (count the lifecycle costs). That bargain probe didn't just cost $1,200. It cost us three weeks because the vendor's service terms didn't cover expedited shipping. We switched to a system with loaner pools and on-site calibration (and standardized suppliers). The next failure? A replacement arrived in 24 hours. Production never stopped.

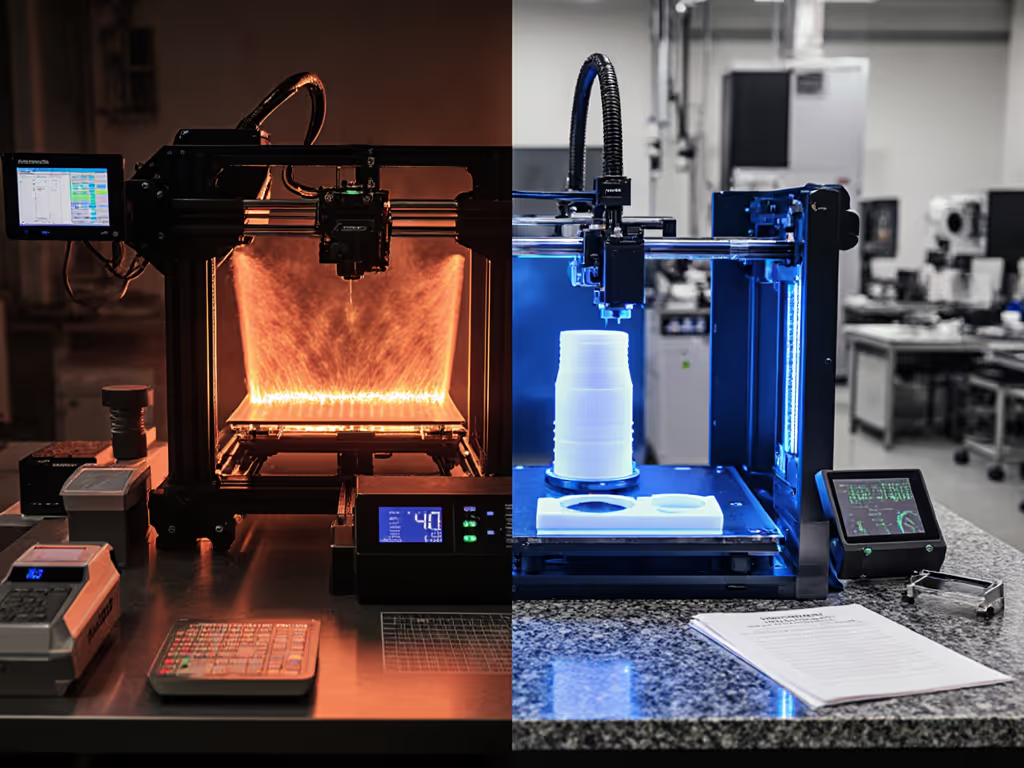

Non-Contact Measurement Comparison: Breaking Down the Tech

I'll dissect the contactless metrology technologies claiming your budget, and focus on where they fail in real shops.

Laser Scanning vs Optical Comparators: The Speed Trap

Laser scanning promises blistering measurement speed comparison for complex geometries (think turbine blades or injection-molded parts). But here's the trap: it chokes on reflective or black surfaces without tedious matte-spray masking (a 20-minute process that kills throughput). I've seen teams lose 3 hours/day fixing "ghost points" from stray reflections. Laser scanning vs optical comparators isn't just about accuracy, it is about unplanned workflow stalls.

Optical comparators (profile projectors) avoid reflection issues but lag in measurement speed comparison. A single lens change can eat 15 minutes during changeovers. For high-mix shops, this becomes a bottleneck. Standardize where it helps: Use optical systems for simple turned parts, and demand auto-focus lenses to shave setup time.

Ultrasonic Thickness Gauging: When Non-Contact Isn't Enough

Ultrasonic thickness gauging gets pitched for in-situ pipe wall measurements (no disassembly needed!). But in reality, surface roughness or scale buildup creates false readings. I've audited plants where undetected corrosion caused leaks because operators didn't redo couplant gel between scans. Surface sensitivity analysis proves ultrasonic requires perfect prep work. For critical assets, I mandate redundant contact verification. The "non-contact" claim here is a liability risk.

Capacitance vs Fiber Optic Sensors: The Cleanroom Bias

Capacitance sensors advertise "nanometer precision" (true if your shop looks like a semiconductor fab). In real-world surface sensitivity analysis, they fail near coolant mist or metal shavings (dirt alters dielectric constants). Fiber optic sensors handle grime better but cost 2.5x more. The TCO math? Only viable for high-value parts where a single defect costs $50k+.

The Leica DISTO X6 Reality Check

Leica Geosystems DISTO X6

This 800-foot laser measurer gets hyped for construction, but let's apply my downtime risk filter:

- Pro: IP65 rating handles shop-floor dust/coolant. Bluetooth sync to SPC systems reduces data-entry errors.

- Con: Camera-based Pointfinder fails in low light (common in cramped machinery). No spare battery option (dead unit = halted layout work).

- TCO Verdict: Justifiable for large facilities doing frequent jigs/fixtures. But for small shops? A $200 optical comparator with granite base lasts decades with basic care. Standardize where it helps: Use DISTO for field measurements but never as primary in-process gage.

Your TCO Checklist: Before You Sign the PO

Don't just compare specs. Audit these before committing:

- Downtime Killers: What's the vendor's guaranteed spares lead time? ("48 hours" written in service terms beats "next-day" verbal promises.)

- Environmental Proof: Demand test data in your conditions (e.g., "How does accuracy drift at 30°C with 80% humidity?").

- Hidden Consumables: Track costs of anti-reflective sprays, air filters, or calibration artifacts (they add $2k/year/part).

- Fleet Standardization: Can you share spares/calibration between sites? One medical client saved $67k/year by standardizing Nikon-compatible optics across 12 labs.

- Training Gaps: Will techs fight the tool? If setup requires an engineer, downtime risk soars. If you're still weighing options, use our tool selection framework to match tolerance to tool class.

Final Verdict: Where Non-Contact Wins (And Where It's a Trap)

Choose non-contact metrology IF:

- You need 100% inspection of high-value parts (e.g., medical implants, avionics)

- Parts are fragile, reflective, or too hot for contact probes

- Measurement speed comparison is critical for high-volume lines

- Your facility has environmental controls (temp, humidity, EMI shielding)

Stick with contact systems IF:

- You're in a dirty shop (foundry, heavy machining)

- You measure deep bores or narrow slots (optics struggle)

- Your budget can't absorb $15k+ calibration costs for non-contact drift

- Audit trails require tactile traceability (common in AS9100) If you're entering aerospace supply chains, see our AS9100 metrology starter kit.

The Bottom Line

Non-contact measurement comparison isn't about "which is better." It's about which system survives your worst-case scenario with minimal downtime. I've killed proposals for $250k scanners because the vendor's loaner program covered just 3 days while our production runs lasted 10. Value is capability sustained over time, not headline specs.

When evaluating any contactless metrology technologies, run this single test: "If a sensor fails tonight, what's the real cost to restart production?" If the answer isn't in your TCO model, walk away. Standardize where it helps, but never at the cost of resilience.

Pay for capability, not chrome (count the lifecycle costs). Your true ROI lives in uptime, not microns.