AR Measurement Tools That Pass Real-World Audits

When my team chased a flashy AR measurement tool's sub-millimeter resolution claim, we triggered $18k in scrap during a critical aerospace run. The app's specs looked flawless, but it crumbled under coolant mist and failed traceability checks. That is why I model AR measurement tools through a metrology engineer's lens: value lives in capability sustained through production chaos, not headline specs. Augmented reality metrology must earn its place on the shop floor by surviving environmental assaults, audit trails, and worst-case downtime scenarios. Below are five non-negotiable criteria my TCO math demands before any AR tool gets near our workflow.

True capability isn't measured in labs, it is proven when coolant floods the floor and auditors demand your uncertainty budget.

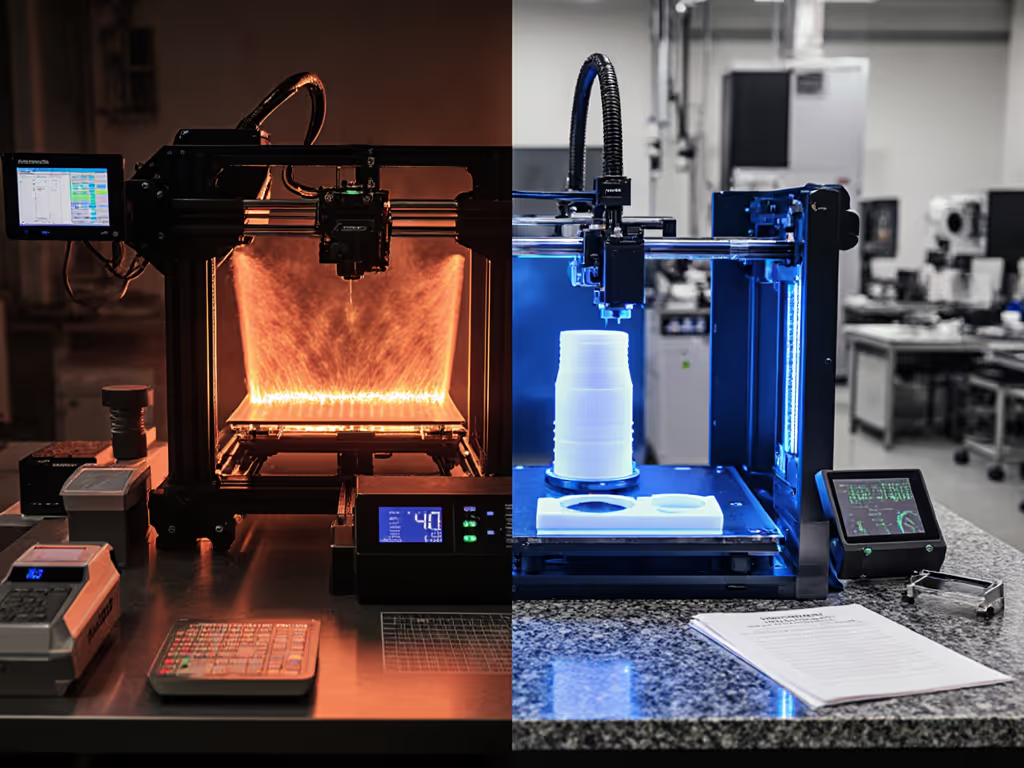

1. Environmental Resilience: Beyond Lab-Grade Hype

Most AR apps promise "laser precision," but ignore real-world sabotage. Coolant vapor? Thermal swing? Vibration? Your tool's spec sheet likely lists accuracy only at 20°C in sterile conditions. Audit survival requires digital overlays for precision that persist when reality bites. Before buying, review our IP ratings for harsh environments to match protection levels to coolant, dust, and washdown exposure. At my facility, we reject any solution without documented environmental limits: temperature drift coefficients, humidity thresholds, and vibration tolerance (measured per ISO 10360-2). One app we trialed claimed 0.5mm accuracy, until ambient temps hit 32°C. Suddenly, perimeter readings skewed by 3.2mm on a machine guard, forcing $7k in rework. Demand concrete test data for your environment, not marketing brochures. If vendors can't provide NIST-traceable drift reports across your operating range, walk away. Capability per dollar plummets when your "precision" tool fails at shift change.

2. Traceable Calibration: Your Audit Lifeline

Here is where most AR tools implode. Metrology is not about taking measurements, it is about proving them. During a recent AS9100 audit, I watched a supplier's AR app rejected because its AR calibration techniques lacked verifiable standards. For a practical refresher on building traceability, see our calibration guide you can adapt to shop-floor audits. No asset ID. No calibration certificate. No uncertainty budget. Game over. Today, I mandate three requirements: (1) Built-in calibration logs with timestamped references to physical artifacts (e.g., "verified against 100mm gage block, cert #AR-2024-772"); (2) Digital signatures to prevent tampering; (3) Integration with your QMS to auto-populate calibration intervals. Apps like PLNAR pass this by embedding ISO-compliant calibration workflows, but check their spares list. If a sensor fails, does your loaner arrive in 24 hours or 3 weeks? Pay for capability, not chrome, count the lifecycle costs.

3. Real-Time Validation: Stop Guessing, Start Auditing

Real-time measurement visualization is useless if it can't self-diagnose. During a medical device calibration run, our AR scanner showed perfect bore alignment, until I tested it against a ring gage. Turns out, its "accuracy" relied on perfect lighting. Smart tools embed validation into the workflow: prompt users to scan verification artifacts between jobs, or auto-flag readings outside Cpk limits. To see how small biases snowball into scrap and rework, read our measurement error types guide. The AR Ruler app nails this with its angle tool (before measuring a turbine blade, it forces a 90° calibration against a known square). But crucial: Can you export that validation log? In regulated industries, auditors demand proof that every measurement chain is intact. If your app's data vanishes when you close it, its TCO math is worthless. Downtime risk skyrockets when you can't reconstruct why a reading failed.

4. Hands-Free Workflow Integration: Easing Technician Strain

Forget "cool factor." In a noisy shop, gloves-on precision work, hands-free measurement is non-negotiable for safety and repeatability. I've seen technicians drop phones trying to pinch-zoom on AR overlays mid-task, costing $4k in scrapped titanium. Approved tools sync with voice commands ("Log measurement") or foot pedals to freeze readings. But integration depth makes or breaks ROI. Quick Measure shines here: on Samsung shop-floor tablets, it pipes data straight into SPC charts via Bluetooth LE (no manual entry). For tools that stream measurements into SPC and MES in real time, explore our wireless SPC integration picks. Compare that to apps requiring photo exports and manual transcribing. One aerospace client saved 11 technician hours weekly by switching to integrated tools. Yet most vendors hide this in fine print: Does their API play nice with your FMS? Check service terms for data lock-in. If migrating data costs 40 hours, your TCO just imploded.

5. Serviceability & Fleet Standardization: The Hidden Cost Killer

This is where I overvalue serviceability (and it is saved my plant repeatedly). That "free" AR app costs $12k/hour when Line 3 stops because it lacks spares lists. Last year, a $99 vision probe app locked us for 17 hours, no replacement calibration files, no vendor support email. Contrast that with our AR Plan 3D deployment: vendors provided on-site loaners and cross-compatible spares across all 12 workstations. Standardization notes from my trials:

- Demand modular spares: Replaceable camera modules, not "whole-unit recalibration"

- Verify cross-device compatibility: Can iPhones and Android tablets share calibration files?

- Lock in service coverage: 4-hour SLA for critical errors, not 5-day "business hours"

One CNC shop cut downtime by 68% after standardizing AR tools fleet-wide. When a sensor failed, they hot-swapped a unit from a non-critical cell (zero production loss). That is capability per dollar.

Actionable Next Step: The Audit-Ready Validation Checklist

Don't gamble on AR measurement tools. Run this 3-point verification before adoption:

-

Stress-test accuracy: Measure a certified artifact covered in coolant mist at 35°C. Compare to dry-room results, does the deviation stay within your tolerance stack?

-

Trace the chain: Ask vendors to demo full calibration documentation export in your QMS format (e.g., PDF certificates with asset IDs, not app screenshots).

-

Simulate downtime: Declare a phantom sensor failure. Time how long it takes to get a working replacement with pre-loaded calibration, not just a box.

If a tool falters here, its specs are fiction. I've seen shops save $200k/year by applying this rigor. Your TCO math isn't complete until it counts downtime risk, service terms, and calibration labor. When audit season hits, you will want tools that prove their worth, not just promise it.