GD&T Measurement Simplified: Gloves-On Techniques for Shops

When your shop runs late-night shifts under takt time, even the best GD&T measurement guide fails if operators can't translate geometric tolerancing into repeatable motions while wearing nitrile gloves. I've seen technicians struggle with complex drawings while coolant sprays their sleeves, only to discover the real issue wasn't the tool specs, but how their hands met the instrument. If operators can't repeat it, it doesn't measure. To align your team's language around repeatability and trueness, read our accuracy vs precision explainer. This isn't about theoretical perfection; it's about building habits that survive shift changes, vibration, and the 3 a.m. rush. Today, we translate GD&T symbols into muscle memory through gloves-on techniques designed for harsh shop floors.

Why GD&T Drawings Fail on the Shop Floor

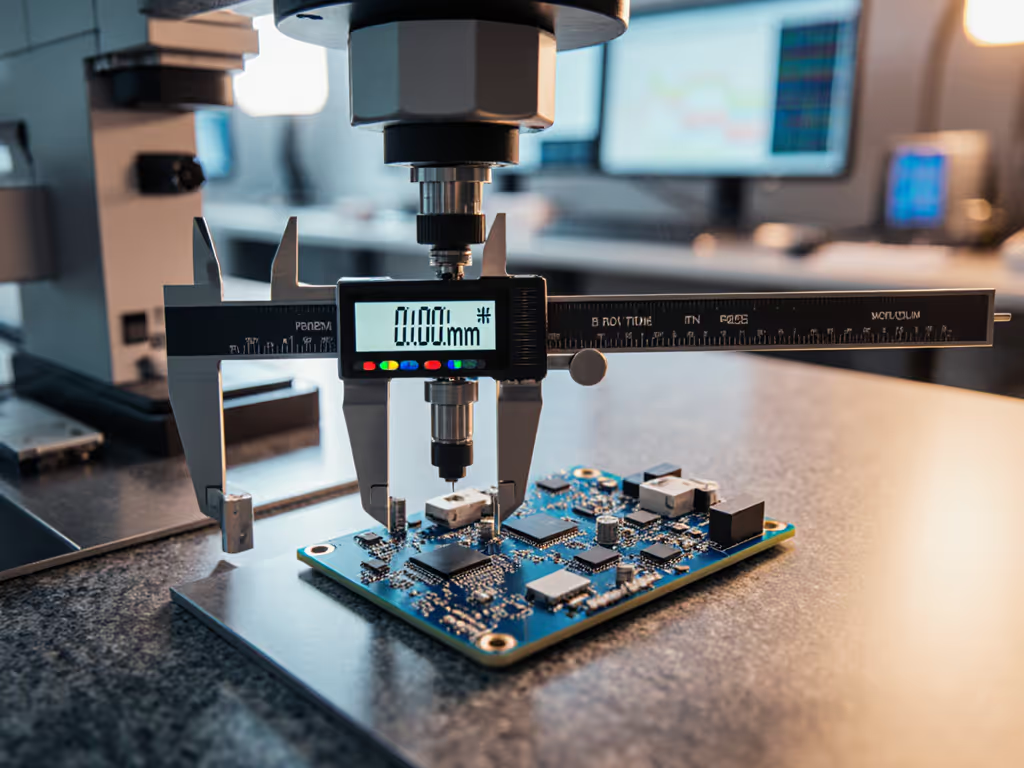

GD&T's brilliance becomes its shop-floor nightmare when engineers design for calipers but production deals with gloves, coolant, and fatigue. That cylindrical tolerance zone in a feature control frame? Meaningless if your operator leans on the indicator probe with inconsistent thumb pressure. Datum references matter little when establishing the primary datum takes three tries because the surface plate is oily. I learned this fixing a 38% GR&R on a medical bracket: the caliper (see digital caliper zeroing) wasn't faulty, it was how thumbs crushed the jaws. A two-minute force-limiting mod and teach-back drill dropped us to 12%. The part never changed; only the human element did.

Repeatability lives in how humans touch tools, not just specs.

The Gloves-On GD&T Translation Checklist

Forget memorizing all 14 symbols. Focus on what moves your hands need to make. Print this checklist for every station:

- For form tolerances (flatness, roundness): "Thumb off the anvil, use palm pressure only" (teach-back cue: "Show me how you'd measure this wearing winter gloves")

- For datum references: "Three-point rock test before locking" (visual anchor: tape a 0.2mm shim under one corner, if it rocks, datum isn't stable)

- For profile measurement: "Scan rhythm = machine feed rate" (safety reminder: never race the spindle, match coolant flow speed)

- For position tolerances: "Square up before zeroing" (teach-back cue: "Explain why we align to datum first, even if it takes 10 extra seconds")

Transforming Feature Control Frames into Action Steps

Most training fails by showing what GD&T symbols mean instead of how to touch the tool. Take position tolerance (⌖| ⌀0.1|A|B|C):

Traditional Approach: "The hole axis must lie within a 0.1mm cylindrical zone relative to datums A, B, C."

Shop-Floor Reality: "How exactly do you place the indicator? At what angle? How hard do you press?"

Operator's 30-Second Workflow (No Engineer Needed)

- Stabilize the datum: Wipe surface with blue shop rag (never bare hands!), then use the "three-point rock test", if it wobbles >1/4 turn, reject the part. No measurement happens until this passes.

- Probe prep: Rub gloves on denim apron to reduce static, then grip indicator like a pencil, never fist-grip. Teach-back cue: "Show me how this feels with frozen fingers."

- Scan motion: Move probe with coolant flow direction, not against it. For cylindrical zones, rotate part (not the probe) to avoid cosine error. Visual anchor: imagine tracing the toolpath on your CNC screen.

- Reading protocol: Call out highs/lows before writing numbers. "Top at 12 o'clock, 0.08mm low" beats squinting at a display covered in swarf.

This converts abstract geometric tolerancing into a repeatable ritual. Last month, a team using this cut false rejects by 22% on turbine blades, without new tools. They just handled the old ones right.

Fixturing Tricks That Survive Takt Time

Datum references collapse when fixtures get knocked or oil-smeared. Instead of expensive granite upgrades:

- The Thumbprint Test: After cleaning the datum surface, press your thumb hard. If the oil reappears inside the print within 30 seconds, the surface isn't stable enough for Grade A measurements. Use a degreasing wipe.

- Glove-Friendly Clamping: Replace wing nuts with quarter-turn cam clamps. Operators can secure parts without removing gloves (critical for consistent force application during profile measurement).

- Coolant Shields: Tape folded cardboard (like a pizza box) above the measurement zone. Blocks spray without costing $500 like commercial shields. If coolant and chips are a daily reality, choose tools with appropriate IP-rated protection to prevent drift and downtime. Safety reminder: never use tape near moving parts.

Train It, Then Trust It: The 2-Minute Technique Audit

You don't need fancy CMM data to spot technique drift. Do this weekly:

- Pick one critical form tolerance measurement (e.g., flatness on a fixture base)

- Have three operators measure it back-to-back wearing production gloves

- Compare their motion, not just numbers:

- Is probe pressure visibly consistent?

- Do they stabilize the part the same way?

- Teach-back drill: "Explain why this matters to the next shift"

If motions vary, you'll get GR&R spikes even with perfect tools. To diagnose whether spikes come from random or systematic sources, review our measurement error types guide. Fix the habit first. One aerospace shop did this every Monday AM; their audit prep time dropped from 4 hours to 22 minutes. They didn't buy new gear, they rebuilt habits.

Your Action Plan for Tomorrow

GD&T only works when the human-tool interface is engineered as rigorously as the part. Tomorrow, before first shift:

- Tape visual anchors at datum points (e.g., colored dots for A/B/C alignment)

- Run the thumbprint test on all primary datum surfaces

- Do the 2-minute technique audit on one high-failure measurement

Track false reject rates for one week. If they drop, you've proven that repeatability isn't about specs, it's about how hands meet tools. Train it, then trust it. When your operators move with confidence under takt time, that's when GD&T stops being a headache and starts preventing scrap. Because in the end, no standard symbol matters more than the muscle memory that survives 12-hour shifts, nitrile gloves, and the relentless tick of the production clock.