Curriculum-Aligned STEM Lab Measurement Tools

When industry auditors examine your facility's measurement processes, they're not just checking equipment. They're verifying whether your team understands the chain of traceability behind every reading. Yet too many STEM programs graduate students with measurement tools that lack proper calibration documentation or environmental controls, creating dangerous knowledge gaps before technicians even enter the workforce. STEM lab measurement tools must bridge the gap between classroom learning and real-world precision requirements, while school metrology equipment should mirror the traceability standards professionals encounter daily in AS9100 or ISO 17025 environments. I've witnessed technicians struggle because their foundational education treated measurement as a simple reading rather than a documented process with defined uncertainty. Trace it, budget it, then trust it under audit (that mantra applies equally to educational settings as it does to production floors).

Why Industry Professionals Should Care About Educational Measurement Practices

Educational measurement tools set expectations for future technicians. When students learn with equipment that obscures uncertainty budgets or lacks proper traceability documentation, they develop habits that cause costly audit failures later. Consider these industry realities that often originate in poorly designed educational programs:

- The resolution fallacy: Students confuse digital display digits with actual accuracy, leading to dangerous overconfidence in readings For a clear explanation of accuracy vs precision, see our concise guide.

- Environmental neglect: Labs ignore temperature coefficients, creating measurement drift that becomes invisible bad data

- Documentation gaps: Students never see calibration certificates with proper uncertainty statements, so they don't grasp their importance

I recall an aerospace auditor once questioning why a supplier's CMM room logs lacked environmental monitoring documentation. When we presented the full chain (showing how our thermometers traced to NMI standards with documented uncertainty), they immediately shifted from skepticism to respect. That lesson applies directly to education: the measurement tools we put in students' hands teach them whether documentation matters.

Core Principles for Selecting Audit-Ready Educational Measurement Tools

Industry professionals evaluating STEM lab equipment must prioritize these non-negotiable elements, regardless of educational context:

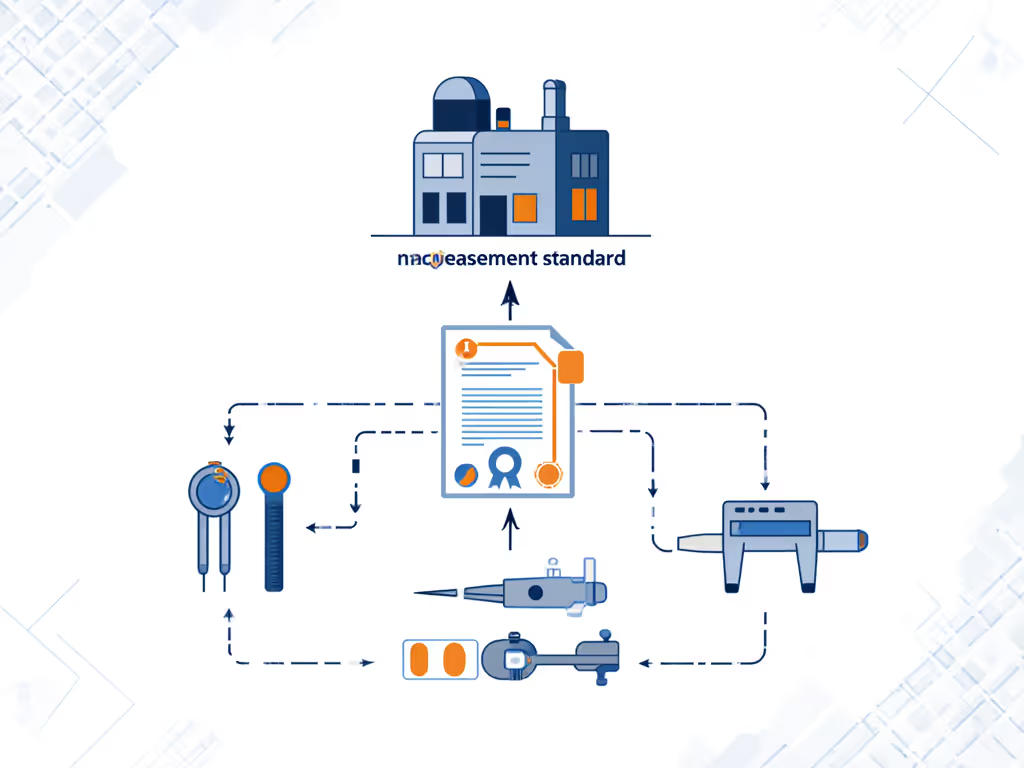

1. Traceability Chains Must Be Visible

Every measurement tool in an educational setting should demonstrate a clear path to national standards. This isn't about expensive certification (it's about teaching proper habits). Look for:

- Calibration certificates showing the complete chain (school instrument → reference standard → NMI)

- Uncertainty budgets that account for environmental factors

- Documentation that survives student handling (laminated cards or digital logs)

"Uncertainty bites at edges" (especially when students transition from classroom exercises to production environments where environmental factors aren't controlled).

2. Environmental Specifications That Match Real-World Conditions

Educational labs often ignore temperature, vibration, and handling effects that industry professionals know compromise measurements. Proper curriculum-aligned instruments must include:

- Temperature coefficients documented in student materials

- Recommended acclimation times before use

- Clear environmental limits for reliable operation

3. Measurement Uncertainty Budgets Built Into Lesson Plans

Students must understand that every measurement carries uncertainty. To build an audit-ready uncertainty budget, follow our step-by-step measurement uncertainty budget guide. Lesson plans should require students to:

- Calculate combined uncertainty for each tool

- Document environmental conditions during measurement

- Recognize when measurement capability approaches required tolerances

Evaluating Educational Measurement Kits: An Industry Professional's Checklist

When selecting educational measurement kits, apply these industry-tested criteria:

Resolution vs. Accuracy Verification

- Test it: Have students measure a known standard at multiple points across the range

- Document it: Require students to calculate bias and repeatability as part of the exercise

- Contextualize it: Show how resolution relates to the process tolerance (never below 4:1 TAR)

Calibration Documentation Requirements

| Component | Industry Standard | Educational Minimum | Red Flag |

|---|---|---|---|

| Certificate | ISO/IEC 17025 accredited | School-signed with uncertainty | "Calibrated per manufacturer" |

| Traceability | Full NMI chain | Reference standard identified | No chain shown |

| Environmental Data | Temp/humidity logged | Room conditions noted | No environmental data |

| Uncertainty Statement | Full budget calculation | Key contributors listed | Missing entirely |

Student-Safe Metrology Considerations

While student-safe metrology requires durability, never sacrifice traceability for ruggedness. The best educational tools:

- Survive classroom handling without compromising measurement integrity

- Include protective cases that maintain calibration during storage

- Feature designs that prevent common errors (e.g., digital calipers with locking mechanisms)

Transporting and Protecting Calibration Integrity: The Overlooked Link

Even the most precise classroom demonstration tools lose their value when handled improperly between uses. I've seen student labs where measurement tools get tossed in drawers or carried unprotected between classrooms, introducing undocumented handling errors that compromise future measurements.

Proper transport requires:

- Dedicated storage containers that protect against shock and environmental shifts

- Clear handling protocols students must follow

- Documentation of transport conditions when moving between environments

dbest Smart Cart Collapsible Basket

The dbest products Smart Cart emerges as a surprisingly valuable component in maintaining measurement integrity during educational transport. While not a measurement tool itself, its role in protecting calibrated instruments makes it essential infrastructure. With its aluminum frame and smooth-rolling design, this cart maintains stability during transport (critical when moving delicate instruments between classrooms or storage). The 110-pound capacity comfortably handles multiple measurement kits with accessories, while the collapsible design ensures it doesn't become clutter when not in use. Most importantly, its stable platform prevents the vibration and impact that would otherwise introduce undocumented uncertainty into your measurement chain.

Building Sustainable Measurement Programs for Educational Settings

Calibration Interval Management

Educational environments often skip proper calibration scheduling, creating dangerous habits. Implement:

- Usage-based intervals: Calibrate after X student measurements rather than fixed time periods

- Peer calibration checks: Have students verify reference standards against known artifacts

- Uncertainty-aware scheduling: Shorten intervals when environmental conditions fluctuate

Documentation Systems That Prepare Students for Industry

Students should practice documenting measurements exactly as they will in professional settings: If you need a framework, our ISO/IEC 17025 accreditation guide shows the documentation disciplines industry expects.

- Require students to record environmental conditions with each measurement

- Implement digital logs showing who, what, when, and uncertainty

- Simulate auditor requests for traceability documentation

The Audit-Ready Classroom: Where Theory Meets Practice

The most valuable STEM labs don't just teach measurement (they teach measurement integrity). When students understand that every reading connects to a chain of traceability, they develop the mindset that prevents costly audit failures in future workplaces.

Consider implementing these practices immediately:

- Require uncertainty statements with every student measurement report

- Display traceability certificates next to each instrument

- Conduct surprise "audits" where students must produce calibration documentation

Educational programs that treat measurement as a documented process (not just a reading) produce technicians who walk into their first industry audit with confidence rather than fear. The tools they learn with set expectations for what's acceptable in professional environments.

Actionable Next Steps for Industry Professionals Supporting STEM Education

If you're partnering with educational institutions or building apprentice programs, take these concrete steps:

- Audit their measurement practices using your internal quality protocols

- Donate outdated but still calibrated tools with full traceability documentation (not junk equipment!)

- Help develop lesson plans that incorporate uncertainty budgets and environmental effects

- Share real audit experiences where poor measurement documentation caused issues

Don't accept educational measurement tools that would fail your internal quality checks. The habits students form with their first caliper or micrometer will follow them throughout their careers. When school metrology equipment meets industry-grade documentation standards, we build a workforce that understands that measurement isn't just about getting a number (it is about knowing how much you can trust that number).

Traceability isn't compromised for convenience in professional environments (and it shouldn't be in educational ones either). The investment in proper tools and documentation today prevents costly rework and audit failures tomorrow. When students learn with STEM lab measurement tools that demand the same rigor as industry standards, they enter the workforce already speaking the language of quality.