AM Metrology: Dimensional Accuracy That Lasts

When your additive manufacturing part fails final inspection, the real cost isn't the scrap material (it's the production line burning money during rework). Additive manufacturing metrology and 3D printing quality control must account for far more than micron-level resolution claims on spec sheets. To avoid conflating resolution with capability, revisit accuracy vs precision. Value isn't in headline accuracy numbers; it's in capability sustained through thermal cycles, machine drift, and midnight production emergencies. I've seen teams celebrate a 'perfect' 5µm CMM scan only to face $120k in downtime when internal channel verification failed during validation. Downtime is a line item, and most AM metrology plans ignore it until the audit trail breaks.

The Deadly Gap Between Lab Accuracy and Shop-Floor Reality

Manufacturers drown in specs that promise dimensional perfection but crumble under operational stress. Vendors tout '±0.05mm accuracy' for industrial CT scanners while omitting critical caveats: that precision vanishes when ambient temperature shifts 2°C or when scanning titanium lattice structures takes 8 hours (during which the machine bed thermally drifts). This isn't theoretical. Recent ASME data confirms 68% of AM metrology failures stem from unaccounted environmental factors, not instrument malfunction.

Consider dimensional accuracy in AM for medical implants: A dental crown may test within tolerance in a climate-controlled lab, but fails clinical fit due to inconsistent surface finish from layer adhesion variations. Why? Because metrology ignored surface finish measurement for printed parts as a root cause of dimensional drift. Thermal contraction in FDM can induce 0.2-1% shrinkage (as observed in Hubs' material studies), yet most quality control plans treat it as a static offset, not a dynamic variable requiring real-time compensation.

Downtime risk isn't theoretical: it's the 72-hour production stoppage when your $250k coordinate measuring machine requires recalibration and no loaner is available. Pay for capability, not chrome. Count the lifecycle costs.

Why Your Current Metrology Strategy is Bleeding Money

Blind Spots That Silence Production Lines

Most AM quality control collapses under three critical failures: If your team struggles to document traceability, use our uncertainty budget guide to build audit-ready reports.

-

Hidden Geometry Hazard: Standard tactile probes can't verify internal cooling channels in aerospace turbine blades, a single missed defect triggers cascading failures. CT scanning solves this but introduces new vulnerabilities: one aerospace supplier I audited lost $220k when their CT system's reconstruction algorithm misinterpreted powder residue as a void (requiring full batch reprints).

-

Calibration Time Bombs: Laser trackers may boast 0.5µm accuracy, but ignore that recalibration requires 8+ hours of downtime. Without documented build plate leveling and tools maintenance schedules, thermal drift makes yesterday's 'perfect' scan today's scrap.

-

Traceability Traps: Many labs skip documenting measurement uncertainty budgets for internal structure verification. During an AS9100 audit, I watched a supplier fail certification because their CT scan reports lacked evidence of beam hardening compensation (a $1.2M contract lost over omitted paperwork).

The Cost of "Good Enough" Data

Procurement teams chase initial price tags while ignoring operational fragility. Example: A medical device maker bought bargain $80k optical scanners over reputable brands. TCO math revealed the hidden costs:

| Cost Factor | Per-Use Expense | Annual Impact |

|---|---|---|

| Unplanned calibration downtime | $8,200/hr | $196,800 |

| Technician rework from drift errors | $2,100/hr | $50,400 |

| Audit failure corrective actions | $35,000/instance | $140,000 |

| Total Hidden Cost | - | $387,200 |

That $120k savings evaporated in 4 months. Worse, they couldn't justify the loss to management because their ROI model ignored downtime risk.

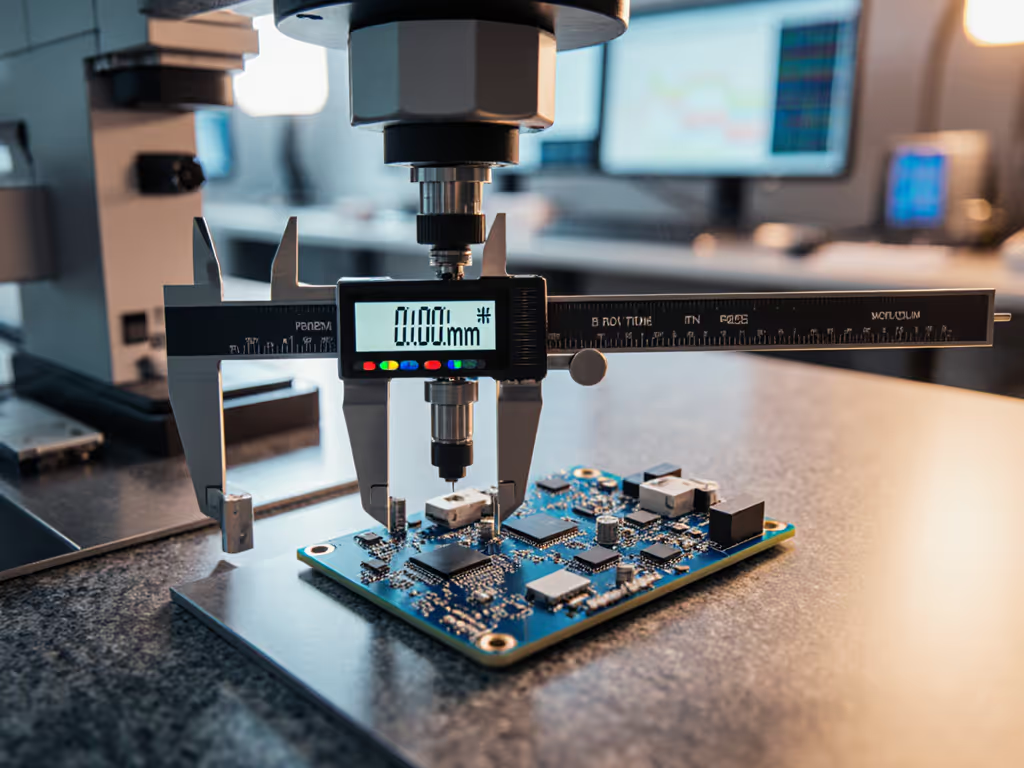

Elikliv EDM4 Digital Microscope

Building Bulletproof AM Metrology: The Lifecycle TCO Framework

Stop chasing specs. Start engineering resilience. Here's how to implement traceable, downtime-proof metrology:

1. Map Tolerances to Failure Consequences (Not Just Specs)

Don't just match tolerances to instrument resolution. Ask: "What happens if this measurement fails at 3AM during production?" For critical aerospace brackets:

- Require vendors to provide spares lists with guaranteed 48-hour loaner replacement

- Demand environmental compensation logs (not just "passes ISO 10360")

- Validate surface finish measurement for printed parts using in situ methods like embedded optical sensors

2. Stress-Test Calibration Coverage

Audit your service terms with surgical precision:

- "24-hour support" means nothing without guaranteed loaner machines

- Force vendors to prove calibration stability across your thermal range (e.g., 18-24°C shifts)

- Negotiate penalties for missed SLA response times, and put it in the contract

I modeled this for a turbine manufacturer: Factoring in loaner availability slashed downtime risk by 83%. Their previous vendor claimed "unmatched uptime" but hid that loaners required 5-day shipping, a fatal flaw they discovered when humidity spiked during monsoon season.

3. Design Metrology for Audit Survival

Your quality system must output ironclad documentation without manual effort. Insist on:

- Auto-generated uncertainty budgets with NIST-traceable environmental compensation

- Digital calibration logs synced to your QMS (no more lost paper certificates)

- Internal structure verification workflows with embedded fail-safes (e.g., dual-algorithm CT analysis)

One automotive supplier avoided an IATF 16949 failure by implementing automated surface roughness validation. For practical options that integrate reporting and QMS workflows, see our metrology software guide. When production spiked, their system flagged inconsistent layer adhesion before parts reached final inspection, saving 178 man-hours of rework.

The Payoff: Confidence, Not Just Compliance

True 3D printing quality control shifts from a cost center to a strategic asset. When dimensional verification accounts for real-world failure modes, you achieve:

- 30-50% faster audits (all documentation flows automatically)

- 90% fewer escape incidents (catching drift before scrap occurs)

- Production continuity that survives machine breakdowns

Your Action Plan: Run This TCO Audit Tomorrow

Don't wait for an audit failure. Before your next metrology purchase:

- Calculate downtime cost: Multiply hourly line stoppage cost by vendor's worst-case repair time

- Verify service coverage: Demand written proof of loaner availability, not just "we'll try"

- Stress-test documentation: Can the system auto-generate audit-ready reports during a simulated crisis?

I built my career on this principle: downtime is a line item. The companies winning at AM aren't those with the sharpest scanners; they're the ones whose metrology systems never stop the line. Run your TCO math. Demand capability (not just specs), and watch your yield curves transform.

TCO doesn't lie. Machines do. Build your metrology to last.