AI in Metrology: Predictive Systems for Consistent Measurements

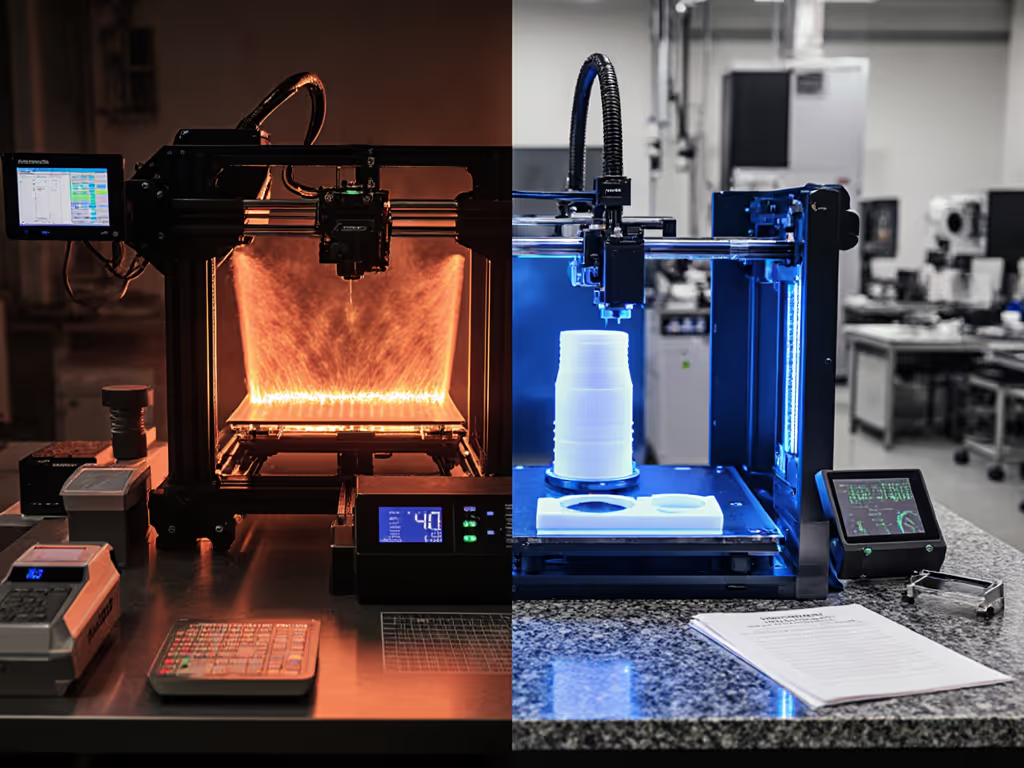

For professionals in regulated manufacturing environments, inconsistent measurements represent more than just technical challenges, they're audit vulnerabilities waiting to happen. When AI in metrology transitions from theoretical promise to practical implementation, it fundamentally reshapes how we approach predictive measurement systems. These systems don't merely collect data; they transform raw measurements into actionable evidence that survives scrupulous audit scrutiny. The integration of artificial intelligence creates measurement environments where documentation becomes intrinsic rather than supplemental, directly addressing one of the most common findings in ISO 9001 and AS9100 audits: missing or inconsistent measurement traceability. For aerospace suppliers, our Aerospace Metrology Starter Kit outlines AS9100- and FAA-compliant tool choices that support traceable measurement workflows. As a quality systems lead who's witnessed countless "measurement failures" that were actually documentation breakdowns, I've seen how properly implemented AI systems turn good measurements into reliable decisions. Evidence beats memory, not just as a slogan, but as a daily operational reality.

How does AI in metrology actually improve measurement consistency from an audit readiness perspective?

Traditional measurement systems generate data, but too often fail to connect it to meaningful evidence trails. AI in metrology addresses this gap through embedded documentation protocols that automatically create revision-controlled records with every measurement. Consider thermal drift in dimensional measurements (a common root cause of discrepancies during audits). Predictive measurement systems analyze historical environmental data alongside real-time temperature readings to establish dynamic correction factors, with each adjustment documented through version-controlled algorithms. This creates a closed-loop evidence trail that survives audit pressure.

Controlled language and revision callouts aren't merely bureaucratic requirements, they're the scaffolding that transforms measurements from isolated data points into audit-ready evidence.

The difference between a failed and passed audit often comes down to whether your measurement system can demonstrate how it reached a particular conclusion, not just what the conclusion was. When I've implemented these systems, I've seen audit teams move from questioning measurement validity to simply verifying documentation completeness. The systems that succeed long-term are those designed with conservative acceptance criteria from the outset, never promising capabilities beyond what can be consistently documented and verified. Think of it as building your measurement evidence chain before you need it under pressure, just like proper revision control on a calibration SOP prevents stop-ship events.

How can we integrate predictive measurement systems without compromising our documented quality management processes?

Integration requires treating AI systems as documented work instructions rather than standalone tools. Begin with defining clear acceptance criteria for any AI-generated output that will be used for conformance decisions. For instance, when implementing machine learning for quality control, your SOP should specify: 1) The training data parameters with documented sources, 2) The uncertainty budget for AI-predicted values, and 3) The documented process for operator intervention when measurements approach tolerance limits.

Document control remains paramount, every model iteration requires a formal revision callout with change justification. I've seen teams derail promising AI implementations by skipping this step, treating model updates as "just software improvements" rather than controlled process changes. When your automated inspection systems automatically flag potential non-conformances, your quality system must document how those flags were generated, investigated, and resolved.

Evidence links must survive the transition from measurement to decision, without them, you're building compliance on shifting sand.

Successful integration respects your existing quality framework while enhancing it. Keep risk notes visible in your AI implementation plan, highlighting where human verification remains essential. This approach not only passes audits but actually reduces audit preparation time, as the evidence trail becomes self-documenting rather than something your team scrambles to assemble when notified of an upcoming audit.

What are the most significant compliance risks when adopting AI-driven metrology systems?

The greatest risk isn't technical failure, it's documentation gaps that undermine evidentiary value during audits. Chief among these is the "black box" problem, where AI systems generate results without transparent methodology. From an ISO/IEC 17025 perspective, every measurement must include documented uncertainty estimates; when AI modifies those estimates, your documentation must explicitly show how.

Another critical risk involves version control for AI models. When your smart metrology software receives updates, your quality system must treat these as formal process changes requiring validation and documented approval, exactly as you would for physical calibration equipment. I've seen organizations fail AS9100 audits because they treated software updates as routine maintenance rather than controlled process changes.

For data-driven measurement systems, the risk of undocumented data lineage represents a major audit vulnerability. Every data point feeding into your AI system must have traceable documentation showing its origin, transformation path, and validation status. When measurement systems operate autonomously, your quality records must document not just the results, but the process that generated them (including environmental conditions, model versions, and any operator interventions).

Remember: if it isn't documented, it's hope, not evidence under pressure. Conservative implementation means starting with narrow AI applications where documentation pathways are clear, then expanding as your team masters the evidence-generation requirements. The most audit-resilient organizations treat AI documentation requirements as more stringent than traditional measurement systems, not less.

How do predictive measurement systems impact measurement system analysis (MSA) requirements?

AI fundamentally changes, but doesn't eliminate, MSA requirements. Predictive measurement systems introduce new variables that require expanded GR&R studies. Your MSA now must evaluate not just the physical measurement device, but the entire AI-assisted process including data pipelines, model versions, and environmental compensation algorithms.

Document control becomes more critical than ever. When implementing machine learning for quality control, your MSA documentation must include:

- Version-controlled model specifications

- Training data parameters and sources

- Uncertainty propagation calculations through the AI pipeline

- Defined intervention thresholds for operator verification

I've helped teams streamline their MSA processes by building evidence links directly into their AI systems, ensuring that every measurement automatically generates the documentation trail required for audit verification. This approach converts what could be a documentation burden into a competitive advantage during audits, where teams using traditional systems still scramble to assemble evidence.

Conclusion: Building Audit-Ready AI Measurement Systems

The true value of AI in metrology isn't faster measurements, it's the ability to generate trustworthy evidence at the speed of production. As you implement predictive measurement systems, remember that consistency and documentation convert good measurements into reliable decisions. The most successful implementations treat documentation as an integral system component rather than an afterthought, ensuring that evidence beats memory when it matters most.

For those ready to explore deeper, I recommend examining case studies from organizations that have successfully navigated the transition from traditional measurement systems to AI-enhanced environments while maintaining audit readiness. Look specifically for implementations that document their evidence-generation protocols alongside their technical specifications, these provide the most valuable lessons for building systems that perform equally well on the shop floor and under auditor scrutiny.